Updated 8/20/25

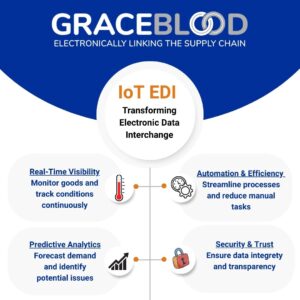

The Internet of Things (IoT) and Electronic Data Interchange (EDI) may sound like separate technologies, but together they form a powerful combination for modern supply chains. IoT devices capture real-time, event-driven data from trucks, warehouses, and even vending machines, while EDI platforms provide the standardized language to transmit that data between business partners. The result? Smarter, faster, and more reliable operations that can dramatically reduce costs and increase customer satisfaction.

Table of Contents

- The Evolution of IoT and Its Relevance to EDI

- Real-World Applications of IoT EDI

- Key Benefits of IoT EDI

- The Future of IoT EDI

The Evolution of the Internet of Things and Its Relevance to EDI

From RFID to IoT: A Brief History

The concept of IoT dates back to the late 1990s, when RFID tags were first used to track goods. Kevin Ashton, who coined the term “Internet of Things” in 1999, envisioned a world where computers could collect data about physical objects without relying on humans. His point was simple: humans are prone to error, slow to capture information, and limited in attention. Devices, on the other hand, can sense and transmit data automatically.

Fast forward to today, IoT includes GPS-enabled trucks, warehouse sensors, smart shelves, and even home appliances—all producing real-time data.

Why EDI is the Natural Partner for IoT

While IoT generates the data, EDI solutions are what make the data useful in business transactions. EDI provides a standard format for exchanging purchase orders, invoices, shipment notices, and compliance documents between companies. When IoT data is fed into these documents—temperature readings into an 856 ASN, GPS data into a shipment update, or inventory levels into an 850 PO—businesses achieve a level of data integrity and automation that wasn’t possible before.

Many of these integrations happen through modern cloud-based EDI platforms, which are designed to handle the constant, high-volume data streams generated by IoT devices. Cloud deployment ensures scalability, security, and the flexibility to connect with trading partners worldwide.

In other words, IoT creates the signals, and EDI translates them into actionable business intelligence.

Real-World Applications of IoT EDI

Cold Chain Monitoring and Compliance

In industries like food and pharmaceuticals, temperature monitoring is a non-negotiable requirement. IoT sensors inside trucks, containers, and warehouses constantly record environmental conditions. With IoT EDI, this data flows directly into EDI transactions such as the 856 Advanced Shipment Notice, providing proof of custody and ensuring compliance with safety standards. This not only protects consumer health but also builds trust between suppliers, carriers, and buyers.

Beyond real-time monitoring, companies can also use predictive analytics on IoT EDI data to anticipate potential cold chain failures before they happen. For example, if temperature fluctuations show a trend toward instability, predictive models can alert stakeholders and trigger proactive corrective actions—protecting both compliance and product quality.

Real-Time Delivery Visibility with Connected Carriers

Carriers have long been the weakest link in the EDI chain, often providing little more than a tracking number. IoT changes that. Connected trucks, ships, planes, and trains can now send continuous updates on location, speed, and estimated arrival times. When integrated with EDI systems through web services, this delivery data enables:

- Precise scheduling of staff for receiving deliveries.

- Faster responses to weather or traffic delays.

- Greater transparency across the value chain.

IoT EDI turns the carrier into a proactive contributor rather than a passive participant in supply chain communication.

Smart Inventory and Automated Ordering

Beyond transportation, IoT EDI applies to inventory management. Imagine a vending machine or retail shelf that automatically monitors stock levels. When items run low, the device itself can generate an EDI 850 Purchase Order to restock. With Global Location Numbers (GLNs), it can even specify the exact location of the device or shelf. This creates a closed-loop system where machines not only detect demand but also trigger supply without human involvement.

Key Benefits of IoT EDI

Greater Supply Chain Data Visibility

IoT EDI provides real-time visibility into where goods are, what condition they are in, and when they will arrive. By feeding sensor and location data directly into standardized EDI documents, companies can eliminate blind spots in their operations.

Operational Efficiency and Automation

By removing the need for manual data entry and human monitoring, IoT EDI reduces errors and accelerates workflows. From shipment notifications to automated reordering, processes that once required multiple steps can now happen instantly. When powered by a cloud EDI solution, this efficiency scales globally, enabling companies to onboard new partners quickly and process millions of IoT-driven messages without disruption.

Improved Compliance and Customer Confidence

For industries under strict regulatory oversight, IoT EDI creates digital proof of compliance. Cold chain data, for example, can be embedded in EDI transactions to satisfy both regulators and customers. This transparency fosters stronger business relationships and customer trust.

Smarter Forecasting with Predictive Analytics

IoT EDI doesn’t just provide visibility into what’s happening now—it creates a rich dataset for predictive analytics. By analyzing IoT sensor readings alongside historical EDI transactions, businesses can forecast demand, identify potential delays, and prepare inventory and staffing accordingly. This forward-looking capability reduces risk and increases agility.

The Future of IoT EDI

Event-Driven Cloud EDI Solutions in Action

Traditional EDI transactions have often been batch-driven, with data exchanged at scheduled intervals. IoT introduces an event-driven model, where updates occur in real time as events happen. For example, a truck entering a geofenced delivery zone could automatically trigger an ASN update via IoT EDI.

Devices That Trigger EDI Workflows

Looking ahead, IoT devices won’t just feed data into EDI—they’ll initiate entire workflows. A warehouse sensor could detect low stock and automatically generate a purchase order. A machine part nearing failure could trigger an EDI request for maintenance or replacement. This moves businesses closer to a fully autonomous supply chain.

The Role of AI and Machine Learning in IoT EDI

While IoT EDI captures and transmits real-time data, AI and machine learning unlock the insights hidden in that data. For example:

- Predictive Maintenance: ML models can analyze IoT sensor data from machines and vehicles to predict failures before they occur, automatically triggering an EDI service request or spare parts order.

- Demand Forecasting: By combining IoT-generated sales and usage data with historical EDI trends, artificial intelligence can predict spikes or drops in demand, helping businesses adjust purchase orders and inventory levels proactively.

- Anomaly Detection: AI algorithms can spot patterns that humans might miss—such as temperature fluctuations in a cold chain shipment—flagging potential compliance issues and embedding that alert in EDI documentation.

- Predictive Analytics for Demand and Supply: AI models can take IoT sensor data, such as sales from connected devices or shipping activity, and combine it with EDI order history to predict future demand. This allows organizations to adjust purchase orders, optimize transportation schedules, and minimize costly overstocks or shortages.

In short, IoT provides the “what” (real-time events), EDI provides the “how” (standardized communication), and AI provides the “why” and “what’s next” (predictive and prescriptive insights). Together, they create an intelligent supply chain ecosystem capable of not only reacting but also anticipating challenges.

Blockchain Technology: Adding Trust and Traceability to IoT EDI

One challenge with IoT data is ensuring that it’s trustworthy. Sensors can malfunction, data can be tampered with, and multiple parties often need to access the same information. This is where blockchain technology comes in.

By recording IoT-generated data on a blockchain, companies can create an immutable, shared ledger of supply chain events. Combined with EDI, this means:

- Cold Chain Integrity: Temperature or location data from IoT devices can be logged on a blockchain, then tied directly into the 856 ASN. Regulators and customers alike can trust that the data has not been altered.

- Dispute Reduction: When all parties (vendors, carriers, customers) share a single, verifiable version of events, costly disputes over shipment status or product condition are minimized.

- Enhanced Security: Blockchain ensures IoT EDI transactions remain tamper-proof and auditable, which is increasingly important in industries like pharmaceuticals and food distribution.

Blockchain doesn’t replace EDI or IoT—it complements them by adding trust, transparency, and accountability to the supply chain.

Why IoT and EDI Belong Together

IoT and EDI are not competing technologies—they’re complementary. IoT captures what’s happening in the physical world, and EDI ensures that data flows seamlessly across supply chain partners, enhancing B2B integration. Together, they create the foundation for a more resilient, efficient, and transparent supply chain.

IoT EDI is not just the future of supply chain integration—it’s happening now. Organizations in logistics, wholesale distribution, retail and manufacturing that embrace this convergence will gain a competitive edge in efficiency, compliance, and customer satisfaction.

Your supply chain deserves smarter, faster, and more connected solutions. Talk to a GraceBlood EDI expert today and discover how IoT EDI can drive efficiency and growth