With today’s competitive and global marketplace, efficient data exchange is crucial for maintaining competitive advantages and fostering strong partnerships. One of the most vital components of this process is EDI mapping, which serves as the bridge between different systems and formats. In this blog, we’ll delve into the intricacies of map development, its importance, techniques, best practices, and how GraceBlood can simplify your EDI mapping process.

With today’s competitive and global marketplace, efficient data exchange is crucial for maintaining competitive advantages and fostering strong partnerships. One of the most vital components of this process is EDI mapping, which serves as the bridge between different systems and formats. In this blog, we’ll delve into the intricacies of map development, its importance, techniques, best practices, and how GraceBlood can simplify your EDI mapping process.

Table of Contents

What is EDI Mapping?

EDI mapping is the process of converting data from one format to another to facilitate electronic data interchange (EDI) between businesses. In essence, it translates data generated by an enterprise resource planning (ERP) system or other internal application into standardized EDI formats such as ANSI X12 (US standard) or EDIFACT (European standard). In rudimentary terms, the correct fields in your business application need to be matched up to the correct fields in a standardized EDI document. It’s the grownup version of a kindergartener drawing lines between “like items” on a lesson worksheet.

Why is EDI Data Mapping Important?

EDI data mapping is essential for several reasons, primarily centered around accuracy and efficiency. When businesses engage in electronic data exchange, they rely on precise data mapping to translate information correctly. Incorrect mapping can lead to significant issues, such as miscommunications, delayed transactions, and costly errors. For instance, if someone incorrectly maps a purchase order, it could result in the wrong items being shipped, causing delays and frustration for both the supplier and the customer. These mistakes not only impact relationships with trading partners but can also lead to financial losses, damaged reputations, and lost sales opportunities. Therefore, accurate map development is critical for maintaining smooth and effective business operations.

EDI Mapping Techniques

An organization can employ various techniques in map development, each with its own advantages and applications.

Manual Mapping

Manual mapping involves a hands-on approach where data is mapped from one format to another by individuals using their favorite programming tool. Smaller businesses often use this technique for specific transactions that may not justify the investment in automation. While manual mapping can be effective in certain scenarios, it is also prone to human error, can be time-consuming, and may not scale well as a business grows.

Purpose-Built Mapping

Purpose-Built EDI mapping utilizes translation software tools to streamline the mapping process. This technique significantly reduces the potential for human error and accelerates the conversion of data formats. Automated tools can handle large volumes of transactions and adapt to changes in EDI standards or trading partner requirements more easily than manual methods. This efficiency is particularly beneficial for larger organizations or those with multiple trading partners, where accuracy and speed are paramount.

Mapping with Pre-Built Templates

Using pre-built templates for EDI data mapping can drastically cut down on setup time and reduce the likelihood of errors. Many EDI solutions offer templates that align with common industry standards and practices, allowing businesses to quickly implement mappings without starting from scratch. This approach not only saves time but also ensures that best practices are followed, enhancing overall data quality. Another way to employ this practice is to copy an existing map and update for a new trading partner. This allows you to not have to reinvent wheel every time you onboard a new partner.

Best Practices for EDI Mapping

Implementing best practices in EDI mapping is essential for optimizing processes and minimizing errors. Here are some key strategies:

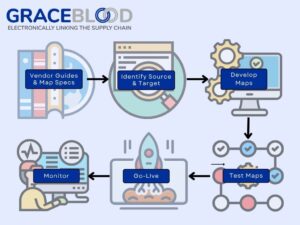

Thorough Planning and Understanding of Business Needs

Before initiating the mapping process, it’s crucial to have a clear understanding of your business needs and the requirements of your trading partners. This planning stage helps teams identify what data they need to exchange and how to structure it. For help with this step, check out our Onboarding Checklist, and set up your onboarding process for success.

Regular Testing and Validation

Once the EDI maps are created, regular testing and validation are vital to avoid errors during live transactions. Conducting tests with sample data can help ensure that the mappings work as intended and that any discrepancies are identified and resolved before actual data exchange.

Utilizing Map Templates and Tools

Incorporating mapping templates and specialized tools can streamline the EDI mapping process. These resources can facilitate quicker setups and help maintain consistency across various transactions, reducing the risk of errors.

Continuous Monitoring and Optimization

After deployment, it’s important to continuously monitor EDI transactions and mappings. Regularly reviewing performance and addressing any emerging issues can help maintain data accuracy and efficiency over time. It’s also worth mentioning that mapping specifications can change over time, either due your partner to migrating to a new EDI version OR your partner migrating to a new ERP system. Retaining a current repository of EDI specs for all of your partners is paramount.

Collaborate Across Departments

EDI mapping often involves multiple departments, including IT, finance, and supply chain. Fostering collaboration between these teams ensures that all stakeholders align and that the map development process effectively meets the organization’s needs.

How GraceBlood Can Simplify Your EDI Mapping Process

At GraceBlood, we understand the complexities involved in EDI mapping and are dedicated to helping businesses navigate these challenges. Our expertise and tools are designed to streamline the map development process, reducing errors and improving speed. We offer a range of services tailored to meet your specific EDI needs, from EDI implementation to professional services and EDI analytics. Our advanced solutions can automate many aspects of the mapping process, allowing you to focus on core business operations while we handle the intricacies of EDI.

If you’re looking to enhance your map development capabilities and improve data exchange efficiency, reach out to GraceBlood today. Our team of experts is ready to assist you in handling your EDI mapping requirements, ensuring your B2B processing operates smoothly and effectively in today’s interconnected world.